Fire resistant and fire retardant cable sheaths are esign to resist combustion anda limit the propagation of flames. Low smokes cables have a sheath designed to limit the amount of smoke and toxic halogen gases given off during fire situations. Fire Resistance Cables are requested for buildings especially hight safety requirements, such as: Emergency power supply station,Power stations and industrial plants,mines,under railway stations.Shipbuilding and offshore locations,data processing sites,alarm system,ventilation systems,escalators,lifts,emergency lighting systems, etc.

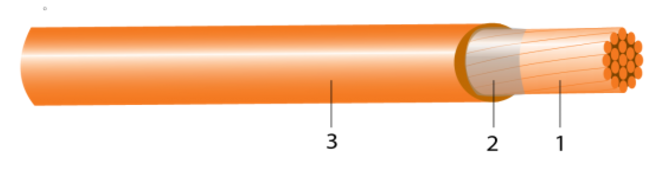

Single Core Non - Sheated 450/750 V

- Conductor: Plain annealed copper wire

- Fire barrier: Mica glass tape

- Insulation: Flame reterdant lew smoke zero halogen (Orange or Other colour are available on request)

Fire Resistant Cable

Fire Resistant Cable is a cable specifically designed to resist fire or to continue conducting electricity for a certain period during a fire. When the cable burns, the key feature of this type of cable is the additional MICA material, which protects against short circuits between the cores.

Once all plastic layers have burned away, MICA—a mineral material made of Alumina-Silicate with a laminar structure—becomes crucial. MICA has a melting point of 1200–1300°C, an insulation resistance of 10¹⁷ ohm·cm at 23°C and 10⁸–10¹⁰ ohm·cm at 500°C, and a breakdown voltage of 150–230 kV/mm. During combustion, MICA bonds strongly to the copper conductor, forming an insulating layer that electrically prevents the current from short-circuiting.

The insulation materials for Fire Resistant Cable (FRC) are XLPE or LSZH (Low Smoke Zero Halogen), and the sheath is made of LSZH. Insulation materials are designed to withstand heat, resist deformation (melting), and avoid producing reactive substances during combustion that could compromise the functionality of MICA tape as a fire barrier. Both the inner and outer sheaths must have flame-retardant properties (as mentioned above), preventing the spread of fire and resisting dripping when exposed to heat.

FRC is tested according to IEC 60331 or BS 6387 standards (as shown in the image below). In these tests, the cable is stretched horizontally, then subjected to voltage up to 1000 V.

- In the IEC 60331 standard, the cable is burned for 90 minutes at a temperature of +750°C.

- In the BS 6387 standard, the cable is burned for 3 hours at a temperature of 950°C + 40°C.

After the fire is extinguished, the current is allowed to flow for an additional 15 minutes, during which no short circuits should occur.